The Role of Diesel Fuel Injection Spare Parts in Enhancing Engine Efficiency

In the realm of modern diesel engines, efficiency and performance are paramount. One critical aspect that significantly influences these factors is the fuel injection system. Within this system, diesel fuel injection spare parts play a vital role in ensuring optimal functionality, which ultimately enhances engine efficiency and reduces operational costs. This article explores the significance of these spare parts, their impact on performance, and best practices for maintenance.

Understanding Diesel Fuel Injection Systems

Diesel fuel injection systems are responsible for delivering precise amounts of fuel into the engine’s combustion chamber. Unlike gasoline engines, diesel engines rely on compression ignition, requiring the fuel to be injected at high pressure. This complexity necessitates the use of high-quality fuel injection components, including injectors, pumps, and related spare parts.

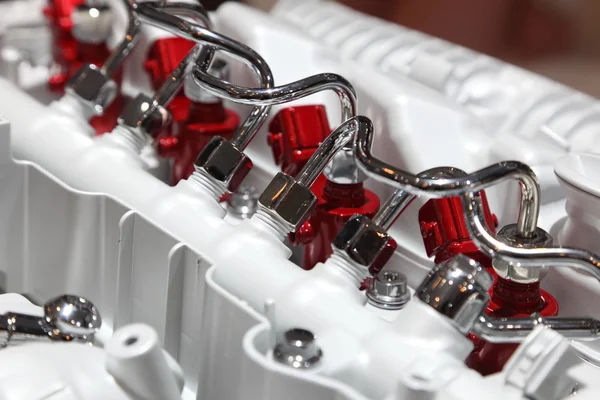

A typical diesel fuel injection system comprises several key components:

- Fuel Injectors: These devices atomize the fuel, ensuring efficient mixing with air for combustion.

- Fuel Pumps: Responsible for supplying fuel from the tank to the injectors at the required pressure.

- Control Modules: These electronic components manage the timing and quantity of fuel injected, adapting to varying engine conditions.

Each component must work in harmony to achieve the desired engine performance and efficiency.

The Importance of Quality Spare Parts

The efficacy of a diesel engine’s fuel injection system is heavily influenced by the quality of its spare parts. Using high-quality diesel fuel injection spare parts ensures that each component performs optimally, thereby enhancing overall engine efficiency. Key advantages of quality spare parts include:

1. Improved Fuel Atomization

Quality injectors ensure precise fuel atomization, which is crucial for efficient combustion. Proper atomization leads to more complete fuel burning, resulting in increased power output and reduced fuel consumption. In contrast, worn or substandard injectors can lead to incomplete combustion, causing loss of power and increased emissions.

2. Enhanced Engine Performance

When diesel fuel injection spare parts are functioning optimally, they contribute to smoother engine operation. This includes better throttle response, reduced noise levels, and minimized vibration. Improved performance translates to a more enjoyable driving experience and increased vehicle lifespan.

3. Cost Savings

Investing in high-quality spare parts can lead to significant cost savings over time. Efficient fuel injection systems improve fuel economy, reducing the frequency of refueling. Additionally, quality parts minimize the risk of engine damage due to poor performance, reducing repair and maintenance costs.

The Impact of Maintenance on Fuel Injection Systems

Regular maintenance of diesel fuel injection systems is crucial for sustaining engine efficiency. Here are some best practices:

1. Scheduled Inspections

Regular inspections of fuel injectors and pumps can help identify wear and tear before it leads to significant issues. Early detection allows for timely replacement of diesel fuel injection spare parts, ensuring the system operates at peak efficiency.

2. Clean Fuel Supply

Contaminated fuel can damage injectors and pumps, leading to decreased performance. It’s essential to use clean, high-quality fuel and install appropriate fuel filters to protect the injection system.

3. Calibration of Control Modules

Modern diesel engines rely on electronic control modules to manage fuel injection timing and quantity. Periodic calibration of these systems ensures they operate correctly, adapting to changing engine conditions for optimal efficiency.

Advances in Diesel Fuel Injection Technology

Technological advancements in diesel fuel injection systems have led to the development of more sophisticated components that offer enhanced performance. For example, common rail direct fuel injection systems allow for multiple injections per cycle, resulting in more efficient combustion and lower emissions.

Moreover, the integration of electronic control modules enables precise fuel delivery adjustments based on real-time engine data. This innovation highlights the importance of using compatible diesel fuel injection spare parts to maintain the integrity of these advanced systems.

Conclusion

The role of diesel fuel injection spare parts in enhancing engine efficiency cannot be overstated. From improved fuel atomization to enhanced overall engine performance, quality components are essential for maximizing the effectiveness of diesel engines. Regular maintenance, along with the use of high-quality spare parts, ensures that fuel injection systems operate at their best, contributing to better fuel economy and reduced emissions.

As diesel technology continues to evolve, staying informed about the latest advancements in fuel injection systems and the importance of quality spare parts will be crucial for operators and maintenance professionals alike. By prioritizing the integrity of diesel fuel injection components, one can ensure not only the longevity of the engine but also its optimal performance in various operating conditions.